Plastic waste pelletizing course

About what and for whom

All about recycling, and specifically about plastic waste pelletizing without a washing line.

For entrepreneurs and production managers

The information of the Course will allow you to avoid many mistakes that we and many other recyclers have made on its’ way.

Only practical useful information that will allow you to understand the processes better, to choose the right equipment, suppliers, and also to save on the purchase of machines, spare parts and consumables significantly.

You can optimally organize production processes, give up some common illusions and make money steadily on this competitive market.

Even an independent study of the Course and application of the information obtained in every-day practice will allow you to save hundreds of thousands dollars. Not taking into account that you will not make many costly mistakes.

For those who only plan to create recycling business, the Course will serve as a roadmap for many key processes and stages.

For those who have long been in this business, the Course will give a complete idea of the way we run it.

We do not theorize general topics. Instead, we give detailed information based on our experience. You will get a full picture of many our processes what we are focusing on, what we use and what tactics we apply in various aspects of our activity. We constantly communicate with many colleagues within plastic recycling industry. And having the full knowledge of the situation from inside, we are sure that many who are not newcomers in this business, will still find useful information in our Course and will be able to really save on something and do something better than they did before.

Why is the price for the Course as it is?

In the plastic recycling market, as in many other business areas, you have two ways to start up:

- To learn everything by yourself going trial-and-error way

- To employ specialists and to commission them to do what they are good at.

If you are going the first way, the information received from our Course will protect you from making a number of costly mistakes and will serve as a guide in making many decisions. The cost of the Course will be regained many times.

Yes, you can find a lot of useful information free on the Internet. But the problem is that there is even more useless and unreliable information there. How can a beginner understand what information is reliable and useful, and what is not, because in many forums people are free to write anything they want, not bearing any responsibility. Unlike the chitchat in various forums, we offer our information in a structured form, we sell it for money, and we are responsible for its adequacy

Writing the Course, we were guided by a simple basic idea - the information should be really useful for the user, should give real opportunities to do something better, to save money, to make some more money, and not to make any specific mistakes.

We evaluated each module, each page of the Course, in terms of the usefulness of the Course for the user. Of course, users can have different level of experience and knowledge in this field. But we are sure that we will reveal something interesting even for the most well-informed persons. And even if we assume that some superprofessional (most likely one of our competitors in the industry) will not find anything new for himself or herself at all, he or she will at least understand our level for this or that subject, and many would pay much more than the Course costs for such information about a competitor.

If you go the second way, in the market you will find a more or less capable specialist for at least $1000 a month. More or less decent production manager will cost you at least $2-3000 per month. Most likely it will be a person who has already supervised such a production. Unfortunately, very many people greatly exaggerate their talents, knowledge and experience. You will understand how competent he or she is only a few months later.

Our Course gives not less, and to a large extent even more information than any such specialist can even just convey you during one month of work, quite apart from providing everything in a structured form.

With the help of our Course you will be able to effectively test your specialist, both when employing, and during his or her work and when he or she makes decisions on various tasks.

What will you learn from the course on «Plastic waste recycling»?

Module no.1: «Materials for recycling»

18 pages72 photos illustrating all mentioned types of waste (60 real pictures from our production sites, 12 pictures from the Internet).

1 PDF file with real laboratory studies of "cross-linked" PE on a DSC device.

Buy now

Module No. 1 — $49

Module No. 1 — $69 (with mailing support)

Buy complete course

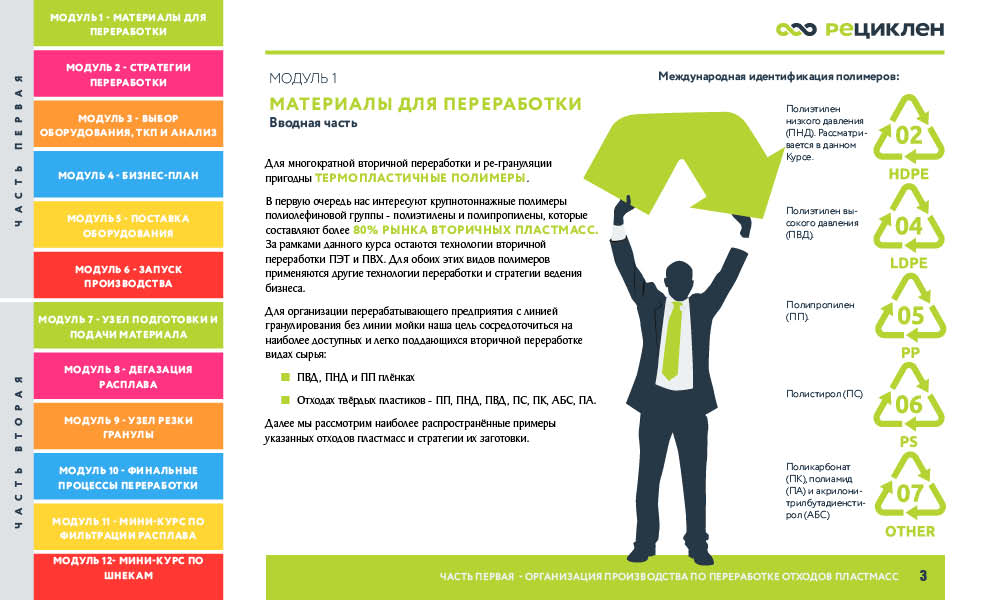

Why does it make sense to focus efforts on the purchase and recycling of large-tonnage thermoplastic polymers - LDPE, HDPE, PP?

What waste of LDPE, HDPE, PP exist and where and how can they be bought.

What problematic waste polymers do not need to be purchased and why.

How to organize business and production of waste LDPE, HDPE, PP without a washing line (a separate large course will be devoted to the recycling plant with a washing line).

What are the requirements imposed on the quality of raw materials and finished products, and what kind of business environment you are going to face in this market.

What principles and tools do we use to find and purchase the necessary raw materials?

The issues concerning purchasing and recycling of PET and PVC are BEYOND the subject matter of the Course, as they are separate topics and businesses, with their own peculiarities both in business processes and in recycling technologies.

Module no. 2: «Recycling strategies»

14 страниц.30 photos illustrating all the mentioned types of equipment, materials, processes (25 real pictures from our production sites and production sites that we visited, 5 pictures from the Internet).

1 link and contacts of a proven supplier of crushers in China.

Buy now

Module No. 2 - $49

Module No. 2 - $69 (with mailing support)

Buy complete course

Two main strategies for recycling of large-tonnage polyolefins.

Which pelletizing lines are required for each of the described strategies and what are the characteristics of these line types.

Which pelletizing lines are NOT suitable for polyolefin waste recycling and why.

Module no. 3: «Technical and commercial quotations of machine suppliers and their comparative analysis»

13 pages.4 real photos from our production sites and from trade and commercial quotations, we received from the manufacturers.

2 (Word and PDF) Equipment Request template files.

2 (Word and PDF) questionnaire files from the machine manufacturers

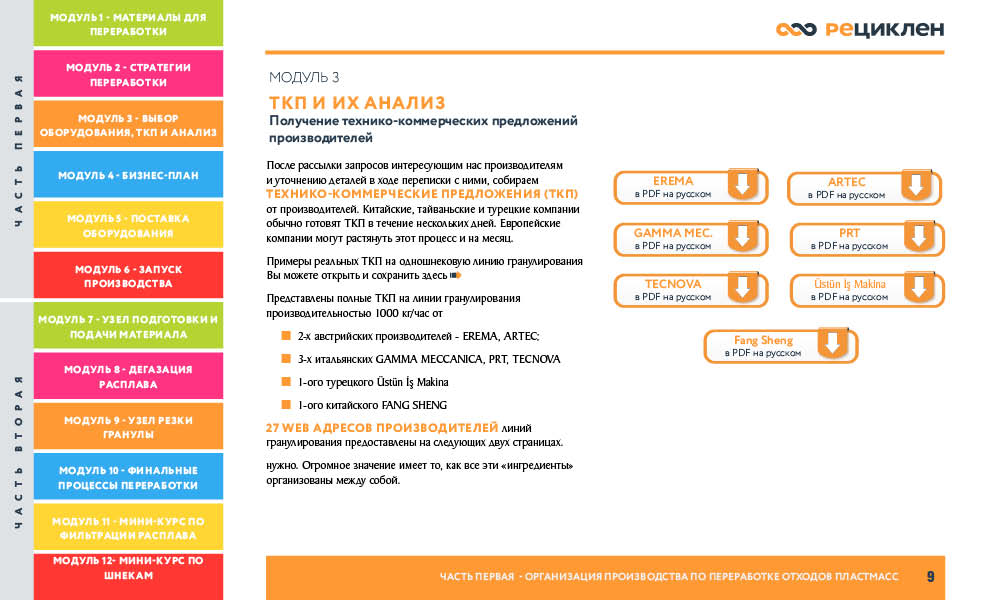

7 real complete trade and commercial quotations from one Chinese, one Turkish, two Austrian and three Italian producers of pelletizing lines.

27 web addresses of proven pelletizing line manufacturers in China, Turkey, Taiwan, Europe, Russia.

Buy now

Module No. 3 - $49

Module No. 3 - $69 (with mailing support)

Buy complete course

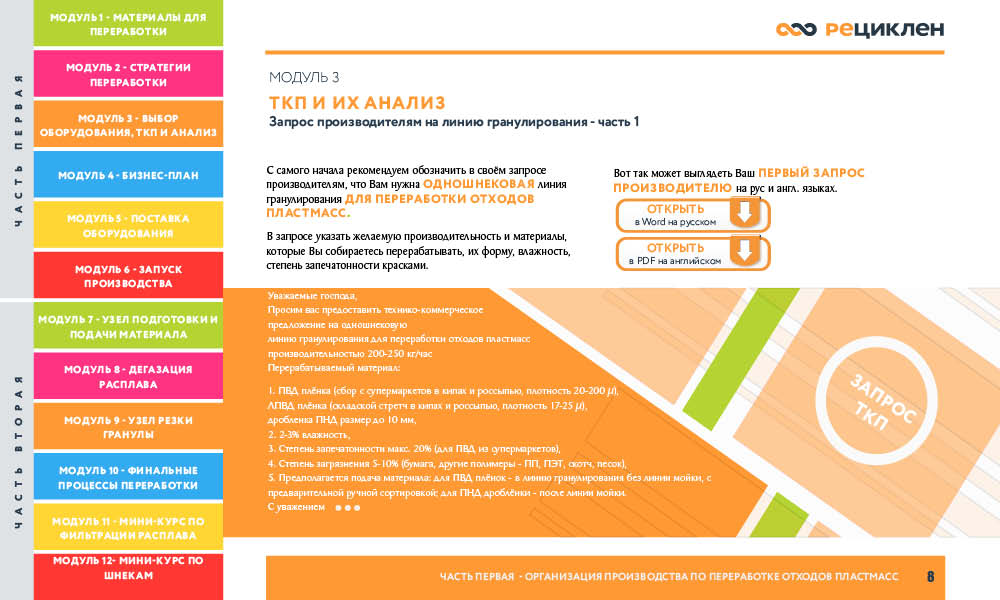

How to draw up a request for a pelletizing line. An example of filling out of a questionnaire. Text templates in Word and PDF.

How to carry out a comparative analysis of complete sales and commercial proposals and how to understand how adequate this or that price per line is compared to others - by the example of seven real sales and commercial quotations from Chinese, Turkish and European manufacturers.

A list of 27 manufacturers of pelletizing lines from China, Taiwan, Turkey, Italy, Austria and Russia, among which 4 companies from which we bought equipment, 14 companies that we visited and 9 companies of permanent exhibitors at Chinaplas

Excel Table, using which you can carry out a comparative analysis of any other pelletizing lines and understand which offer is optimal in terms of price/productivity ratio.

Module no. 4: «Business plan»

6 pages3 (Excel and PDF) files: Real examples of tables with planning of costs and revenues of the recycling company.

1 (Excel) file: options for organizing shift work.

Buy now

Module No. 4 - $49

Module No. 4 - $69 (with mailing support)

Buy complete course

Minimum necessary real sample of the plan of costs and revenues of the recycling company. Real figures of costs and revenues based on our 18 years of experience. On the basis of these templates you can make your own business plan and go by it in making decisions.

How can you organize a profitable recycling company with one or two pelletizing lines, without a washing line.

What mistakes must be avoided, what can you expect and what not.

A table showing the differences in the different schedules of shift work organization and the cost of wages in each of the options.

Module no. 5: «Supply (import) of pelletizing line»

14 pages11 photos (7 real pictures from our production site, 4 photos from the Internet)

12 real documents (in Word and PDF) required to import the equipment (to Russia, as a sample case)

The list of CN codes usually used when importing the pelletizing line and associated units and spare parts.

Buy now

Module No. 5 - $49

Module No. 5 - $69 (with mailing support)

Buy complete course

Three options for acquiring foreign equipment - independently directly and with different stages of involvement of intermediaries. All the pros and cons of each option.

How to make a contract with equipment supplier. Important points that need not be forgotten at the stage of signing of the contract. What it pays to ask the supplier about and what not.

A detailed list of options and spare parts, we recommend to take simultaneously with the pelletizing line.

How to work with logistics companies and Russian customs.

Real samples of all documents on the import of equipment.

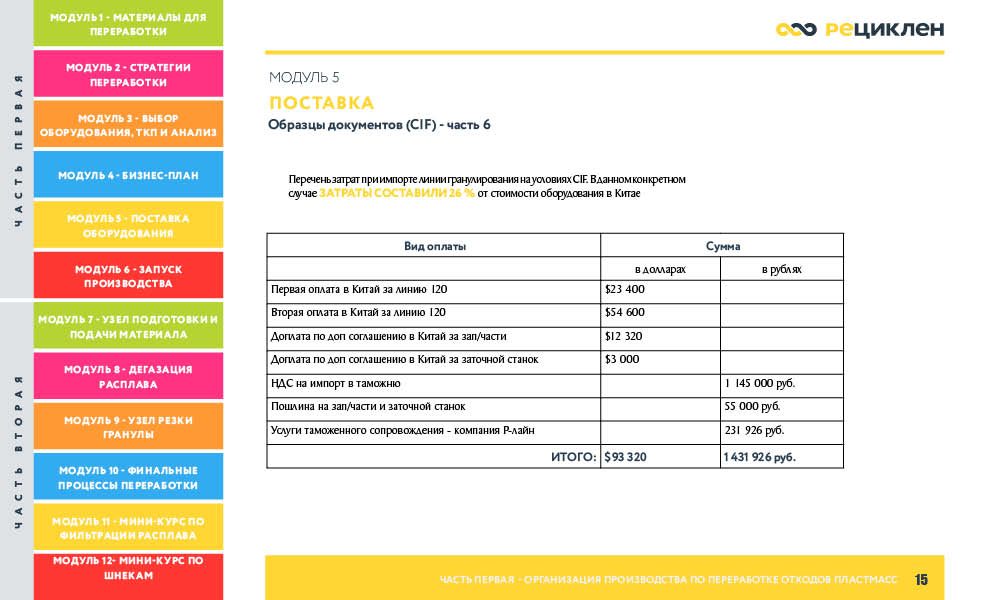

Real cost calculation for equipment import.

Module no. 6: «Commissioning of the pelletizing line»

16 pages35 photos (35 real pictures from our and our equipment suppliers’ production sites)

Buy now

Module No. 6 - $49

Module No. 6 - $69 (with mailing support)

Buy complete course

Do you have to go to the supplier’s plant for the test-run? How should the test-run be carried out? Practical recommendations.

How to organize the shipment at the supplier's plant properly.

How to manage the acceptance and unloading of equipment.

How to prepare the workshop and arrange the installation of the line in place.

Are supplier’s specialists required for start-up and commissioning works.

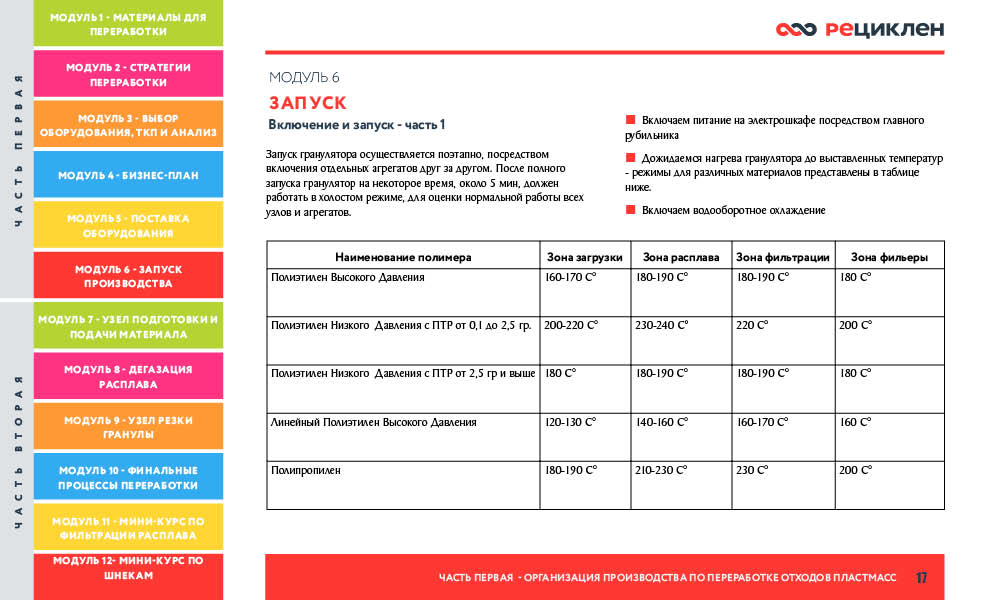

All that is needed for the first start-ups. The start and stop of the pelletizing line’s procedures, examples of temperature regimes for different materials, staff management.

Chief technician’s tips — must-have spare and high-wear parts - photos, descriptions, prices and possible purchasing alternatives. Frequently encountered problems and their solutions.

Module no. 7: «Preparation and feeding of material into the pelletizing line»

14 pages27 photos (22 real pictures from our and our equipment suppliers’ production sites, 5 photos from the Internet)

15 real trade and commercial quotations from the manufacturers.

Buy now

Module No. 7 - $49

Module No. 7 - $69 (with mailing support)

Buy complete course

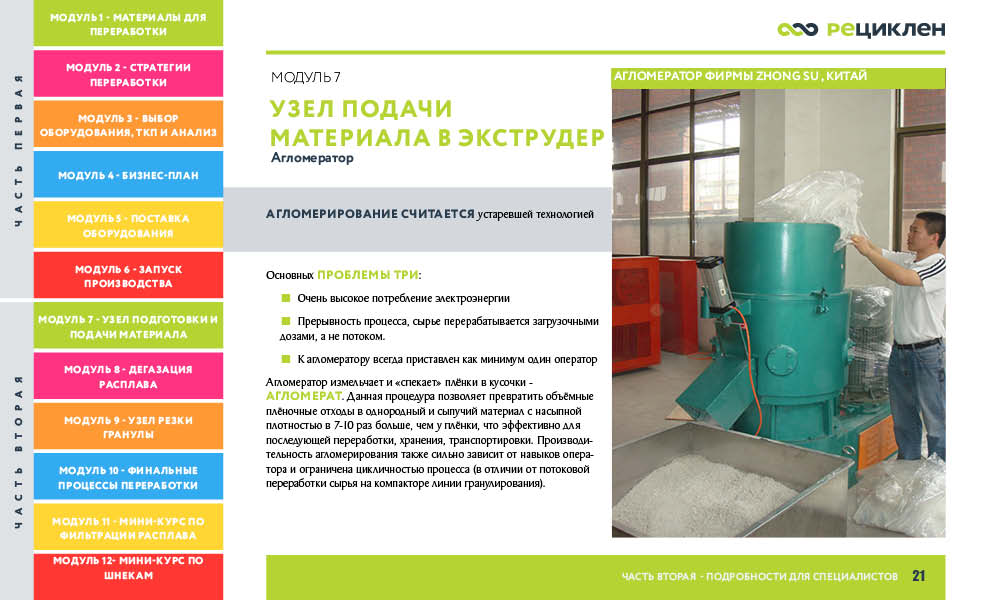

Three types of plastic waste preparation units that are used in recycling before pelletizing.

Details about each of them - a compactor, an agglomerator and a volumetric feeder including:

- how they are arranged, with what raw materials they can work, and with what they can not,

- How they work and what affects the performance and productivity,

- What the problems are and how to solve them

What additional useful dosing devices can be purchased.

The chief technician’s tips — must-have spare and high-wear parts - photos, descriptions, prices and possible purchasing alternatives. Frequently encountered problems and their solutions

Module no. 8: «Melt degassing»

10 pages24 photos (22 real pictures from our and our equipment suppliers’ production sites, 2 photos from the Internet)

Buy now

Module No. 8 - $49

Module No. 8 - $69 (with mailing support)

Buy complete course

Why is melt degassing so important in the plastic scrap recycling?

Two types of melt degassing system.

Details on vacuum and natural degassing including:

- Varieties and features

- How they show themselves in production - advantages and disadvantages

- Which degassing systems are NOT suitable for the plastics waste recycling

The chief technician’s tips — must-have spare and high-wear parts - photos, descriptions, prices and possible purchasing alternatives. Frequently encountered problems and their solutions.

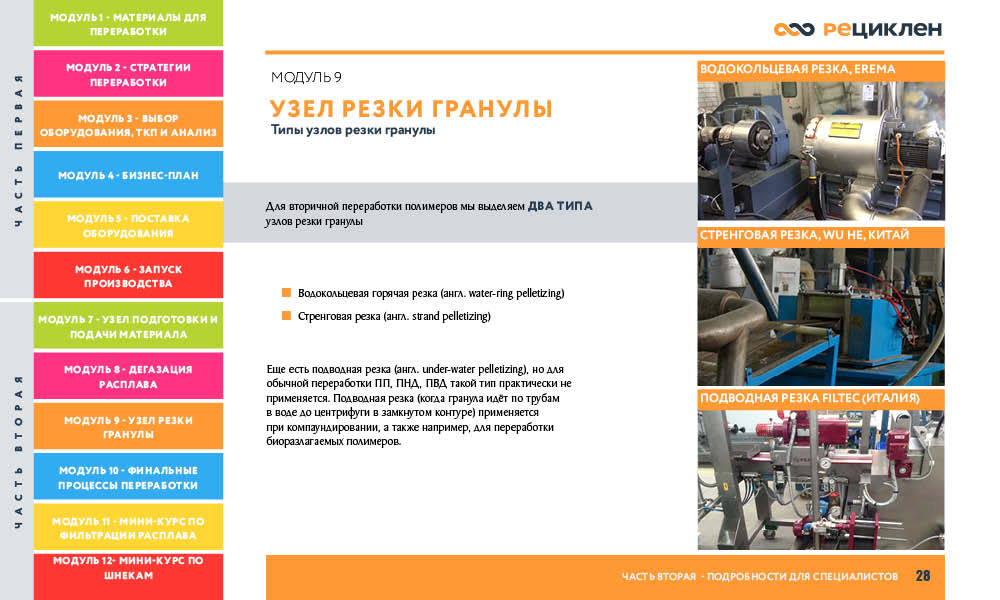

Module no. 9: «Pelletizers»

11 pages23 photos (20 real pictures from our and our equipment suppliers’ production sites, 3 photos from the Internet)

7 links to proven manufacturers

Buy now

Module No. 9 - $49

Module No. 9 - $69 (with mailing support)

Buy complete course

Two types of pellet cutting system in recycling

Details about each of them including:

- The way they work, the raw materials they can work with, and can not work,

- How they work and what affects the quality and productivity,

- What are the problems and how can they be solved?

The chief technician’s tips — must-have spare and high-wear parts - photos, descriptions, prices and possible purchasing alternatives. Frequently encountered problems and their solutions

Module no.10: «Final processes of plastic waste recycling»

14 pages33 photos (10 real pictures from our and our equipment suppliers’ production sites, 3 photos from the Internet)

7 links to proven manufacturers

Buy now

Module No. 10 - $49

Module No. 10 - $69 (with mailing support)

Buy complete course

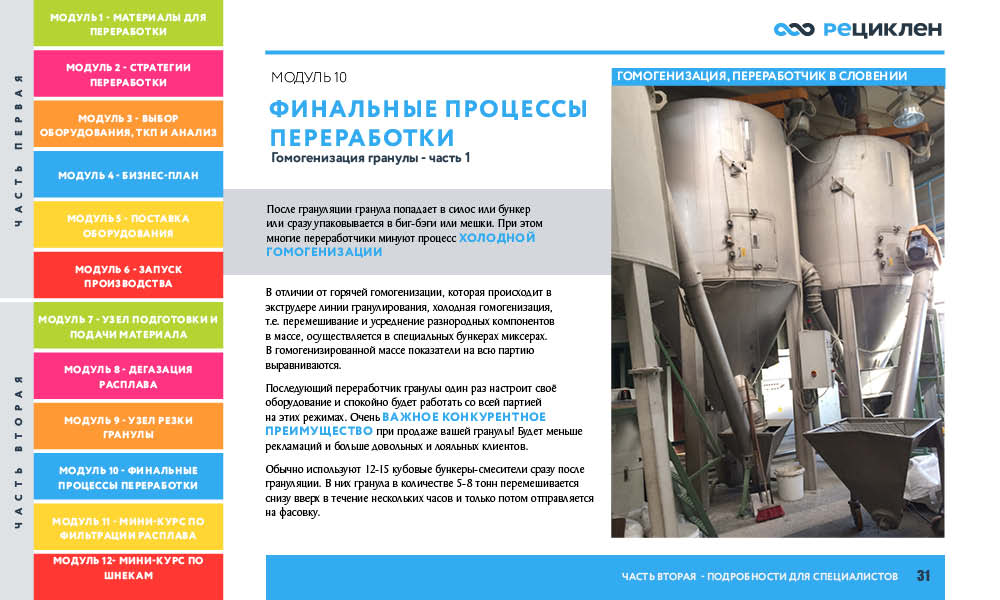

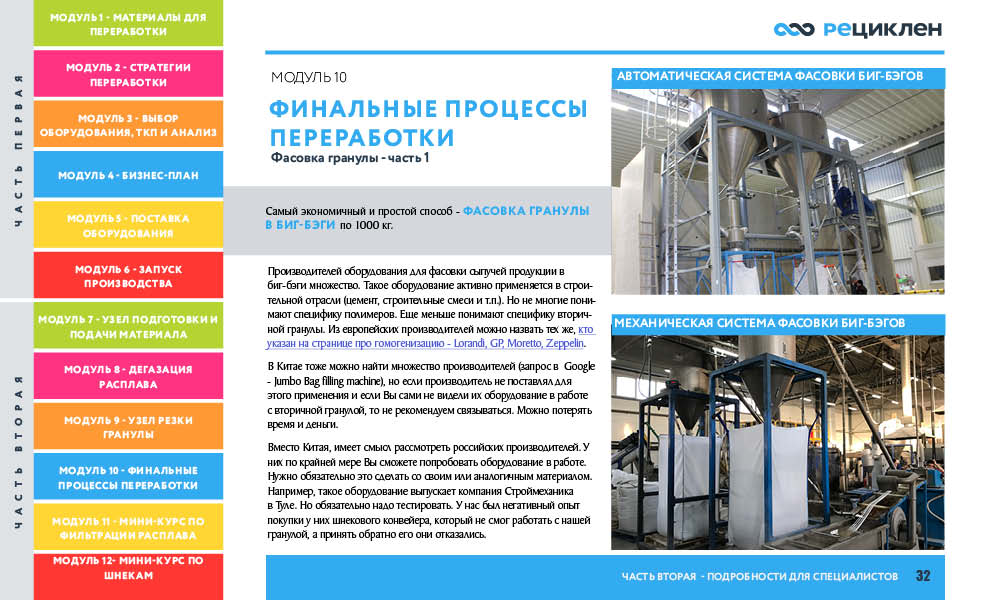

What final processes are important in plastic waste recycling?

- cold homogenization,

- packaging,

- quality control - MFI and others

Module no. 11: «Melt filtration»

25 pages37 photos (26 real pictures from our and our equipment suppliers’ production sites, 11 photos from the Internet)

11 links to proven manufacturers.

Buy now

Module No. 11 - $49

Module No. 11 - $69 (with mailing support)

Buy complete course

Why the melt filtration unit is a fundamentally important element for polymers recycling.

What types of melt filters are suitable for the plastics waste recycling, and which are not and why.

Details on the two types of melt filters most suitable for recycling:

- The way they work, the raw materials they can work with, and can not work,

- How they work and what affects the quality and productivity,

- What are the problems and how can they be solved

- Contacts of proven manufacturers

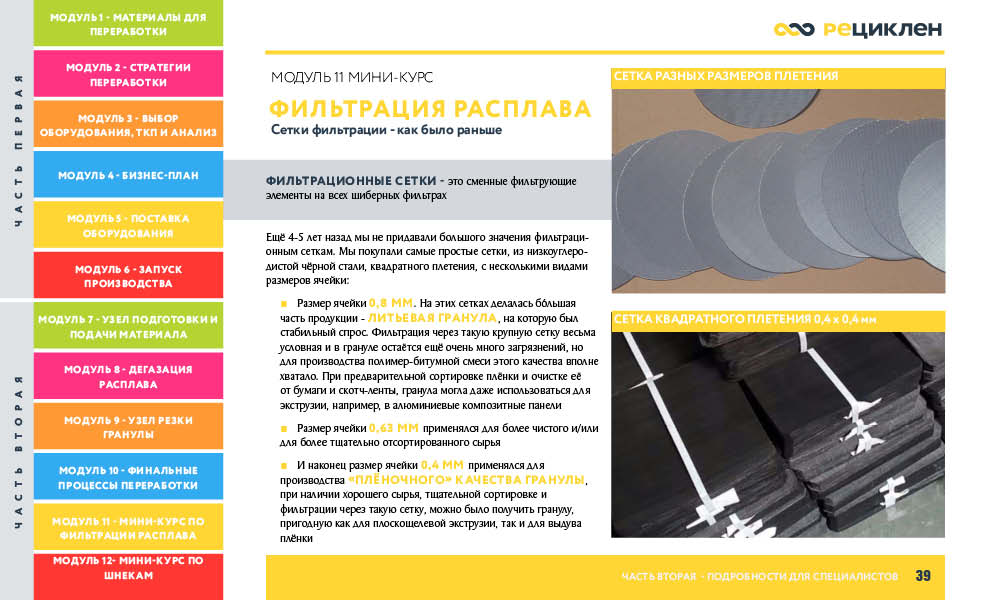

All about replaceable filtration mesh-screens:

- what are the types and kinds

- how to buy the right mesh-screens and not to overpay

- contacts of proven manufacturers, prices and significant differences

- what types of mesh-screens do we use for each material

- how to reuse the mesh-screens - cleaning methods and equipment

- how to organize your own mini workshop for mesh-screens cutting - equipment, tools, prices

Module No. 12: «Screws and Barrels»

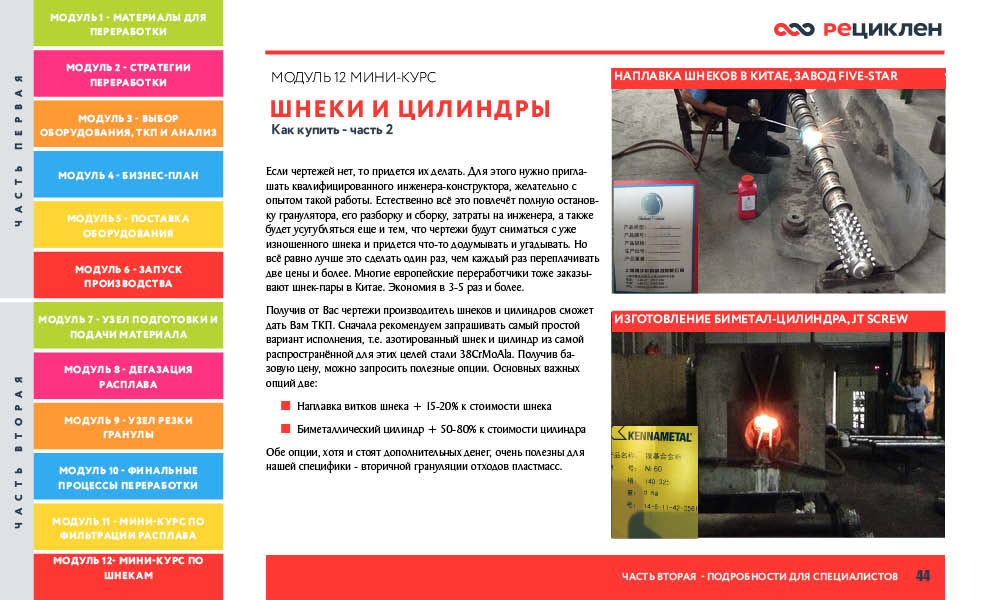

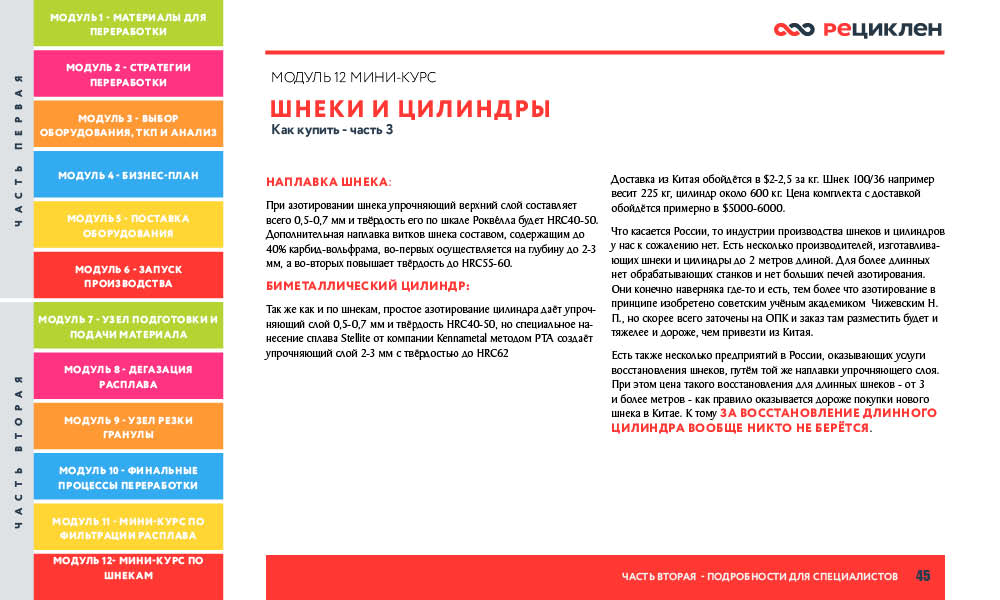

11 pages10 photos (8 real pictures from our and our equipment suppliers’ production sites, 2 photos from the Internet) 20 proven manufacturers of screws and barrels in China, Turkey, Taiwan, Europe.

6 contacts of Russian companies providing screw recovery services

Купить

Module No. 12 - $49

Module No. 12 - $69 (with mailing support)

Buy complete course

What is the problem of rapid wear of screws and barrels in plastic waste recycling.

How to buy new screws and barrels cheaper than the cost of restoring of old ones.

Details about the options — alloys hardening, bimetal, nitriding - what should be done and how much it costs.

Contacts of proven manufacturers in China, Taiwan, Turkey, Europe and Russia

Which screws and barrels can be restored in Russia and the economic feasibility.

Buy complete course

Buy the course before September, 12 and have free fact-finding visit to our plant

After October, 10 2017 the price will be increased 30%

- Full access to all 12 modules

- Self-studying and application in practice

- Full access to all 12 modules

- self-studying and application in practice

- We answer all your questions - once a week,with e-mail sent to all the users of this course. Mailing support will be provided within 3 months after purchasing the course

- Full access to all 12 modules

- Self-studying and application in practice

- We answer all your questions - once a week,with e-mail sent to all the users of this course. Mailing support will be provided within 3 months after purchasing the course

- Fact-finding visit to our RECYCLENE plant

- 2 private and personal consultancy regarding your own recycling project (2 hours each) — detailed observation and study of your case

What else do you want to know about our business?

Write to us and we will include it in our plastic recycling course